In the rapidly growing livestock industry, our client, a leading poultry producer, recognized the need to expand their feed production capacity to meet the increasing demand for high-quality poultry feed.

According to a recent market analysis by the USDA, the global poultry feed market is expected to grow at a CAGR of 4.2% from 2022 to 2027, reaching a value of $280 billion by 2027.To cater to this growing demand, the client sought to install a new 20T/H animal feed production line at their existing facility.

This capacity would allow them to efficiently produce the required volumes of feed while maintaining the desired quality and nutritional specifications for their poultry operations.

Conducting Market Research and Supplier Evaluation

The client’s team conducted an extensive market research and supplier evaluation process to identify the most suitable solution provider for their animal feed production line project.

They considered factors such as the supplier’s technical expertise, customization capabilities, project management experience, and after-sales support.

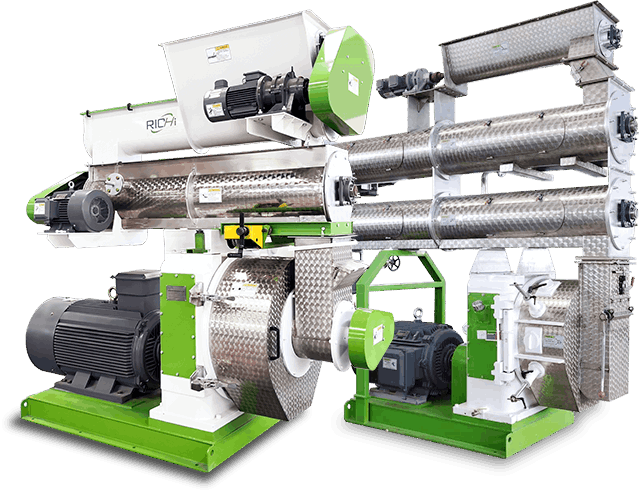

During this evaluation, the client’s team closely examined several potential suppliers, including RICHI Machinery, a leading manufacturer and turnkey solution provider for animal feed production lines.

RICHI Machinery’s reputation for delivering high-quality, customized solutions and their proven track record of successful project implementations were key factors that caught the client’s attention.

Addressing Site Constraints and Layout Optimization

One of the primary challenges faced by the client was the limited space available at their existing production facility. The new 20T/H animal feed production line needed to be integrated seamlessly into the existing infrastructure without compromising the overall operational efficiency.

To address this challenge, the client engaged RICHI Machinery’s team of experienced engineers to conduct a detailed site survey and propose an optimized layout design.

Using advanced 3D modeling and simulation techniques, the RICHI Machinery team analyzed various configuration scenarios and identified the most efficient arrangement of equipment, ensuring smooth material flow and easy accessibility for maintenance.

“The RICHI Machinery team’s attention to detail and their ability to develop a compact, yet highly functional layout for our facility was truly impressive,” remarked the client’s project manager. “Their engineering expertise allowed us to maximize the utilization of our available space while meeting our production targets.”

Ensuring Precise Ingredient Handling and Mixing

Another critical requirement for the client was the ability to precisely control the dosing and mixing of feed ingredients to maintain consistent feed quality and meet the stringent nutritional specifications for their poultry operations.

To address this challenge, RICHI Machinery provided a customized solution that included advanced weighing and batching systems, coupled with a high-efficiency ribbon mixer. The weighing systems ensured accurate and repeatable dosing of each ingredient, while the ribbon mixer delivered thorough and homogeneous blending, minimizing the risk of nutrient segregation.

To validate the effectiveness of this solution, the RICHI Machinery team conducted extensive testing and analysis, including particle size distribution studies and nutrient homogeneity assessments.

The results demonstrated a remarkable improvement in feed quality, with a coefficient of variation (CV) for nutrient distribution below 5%, well within the industry’s stringent standards.

“The level of precision and quality control that RICHI Machinery brought to our feed production line was truly impressive,” said the client’s quality assurance manager. “We have seen a significant improvement in the consistency and nutritional profile of our poultry feed, which has directly translated into better growth performance and feed conversion ratios for our birds.”

Ensuring Reliable and Energy-Efficient Operations

In addition to the technical performance of the production line, the client also prioritized the long-term reliability and energy efficiency of the equipment to minimize operational costs and maximize profitability.

RICHI Machinery’s engineers designed the 20T/H animal feed production line with a focus on durability and energy efficiency. They incorporated advanced manufacturing techniques, premium materials, and energy-saving features, such as optimized motor sizing and heat recovery systems, to ensure the line’s longevity and reduce energy consumption.

According to the client’s operations manager, “The energy-efficient design of the RICHI Machinery production line has resulted in a 15% reduction in our overall energy costs, which has had a significant impact on our bottom line.

Additionally, the reliability and low maintenance requirements of the equipment have allowed us to minimize downtime and maximize our production uptime.”

Comprehensive Training and After-Sales Support

To ensure the smooth and efficient operation of the 20T/H animal feed production line, RICHI Machinery provided comprehensive training for the client’s operators and maintenance personnel.

This training covered topics such as equipment operation, troubleshooting, and preventive maintenance, equipping the client’s team with the necessary skills and knowledge to maintain the production line’s performance.

Furthermore, RICHI Machinery’s dedicated after-sales support team has been available to address any issues or concerns that may arise, ensuring prompt resolution and minimizing production disruptions. The client’s project manager praised RICHI Machinery’s responsiveness and the level of support they have received, stating,

“The after-sales service provided by RICHI Machinery has been exceptional. Their team has been readily available to assist us, and they have consistently demonstrated a deep understanding of our production line and the challenges we face.”

Conclusion

The successful implementation of the 20T/H animal feed production line at the client’s facility is a testament to the expertise and capabilities of RICHI Machinery as a trusted turnkey solution provider.

By addressing the client’s specific challenges, such as site constraints, precise ingredient handling, and energy efficiency, RICHI Machinery was able to deliver a customized solution that has significantly improved the client’s feed production capabilities, product quality, and overall profitability.

The client’s experience with RICHI Machinery’s comprehensive approach, from the initial consultation to the ongoing after-sales support, has reinforced the value of partnering with a reputable and experienced provider in the animal feed production industry.

As the livestock sector continues to evolve and the demand for high-quality feed grows, the client is well-positioned to capitalize on these market opportunities with the help of RICHI Machinery’s innovative solutions.