Introduction

In the age of sustainable agriculture, small-scale organic fertilizer production lines are becoming increasingly popular among local farms and rural cooperatives. These production lines offer an eco-friendly way to manage agricultural waste and improve soil fertility with minimal investment. Unlike large commercial operations, small-scale fertilizer plants are designed to be compact, cost-effective, and tailored to specific local needs.

This article explores how to design a small-scale organic fertilizer production line from scratch, including raw material selection, equipment configuration, process design, cost estimation, plant layout, and practical tips for local implementation.

1. Why Choose a Small-Scale Organic Fertilizer Production Line?

Key Advantages:

- Affordable Investment: Lower capital expenditure compared to large industrial plants.

- Localized Operation: Tailored for small and medium-sized farms.

- Sustainable Waste Management: Turns manure and crop waste into valuable fertilizer.

- Soil Health Improvement: Organic matter enhances water retention, aeration, and microbial activity.

- Quick Payback: Faster return on investment due to low input and high demand.

2. Suitable Raw Materials for Small-Scale Production

Local farms typically have easy access to the following organic materials:

| Raw Material | Characteristics |

|---|---|

| Chicken manure | High nitrogen, requires moisture adjustment |

| Cow dung | Balanced and easy to compost |

| Goat/sheep manure | Rich in nutrients, low in moisture |

| Pig manure | Nutrient-rich, odor requires control |

| Crop residues (straw) | Used for carbon content in composting |

| Kitchen/vegetable waste | Suitable for community composting |

Tip: A proper Carbon/Nitrogen (C/N) ratio of 25–30:1 is essential for effective composting.

3. Production Process Overview

A small-scale organic fertilizer line typically includes:

- Composting

- Crushing

- Mixing

- Granulation (optional)

- Drying (sun-drying or small dryer)

- Screening

- Packing

You may choose to produce powdered or granular organic fertilizer depending on market needs and budget.

4. Process Flow and Equipment Configuration

Option 1: Powdered Organic Fertilizer Line (Simpler and Cheaper)

Process Flow: Composting → Crushing → Screening → Packing

Key Equipment:

- Compost Turner:

- Type: Manual turning or small crawler/groove turner

- Purpose: Speed up fermentation

- Crusher:

- Type: Semi-wet crusher

- Function: Crush compost lumps for uniformity

- Screener:

- Type: Rotary screener

- Use: Remove oversized particles

- Packing Machine:

- Type: Manual or semi-automatic

- Capacity: 1–5 T/h

Advantages:

- Fewer steps

- Low energy consumption

- No need for drying or granulation (Related post: organic fertilizer production project)

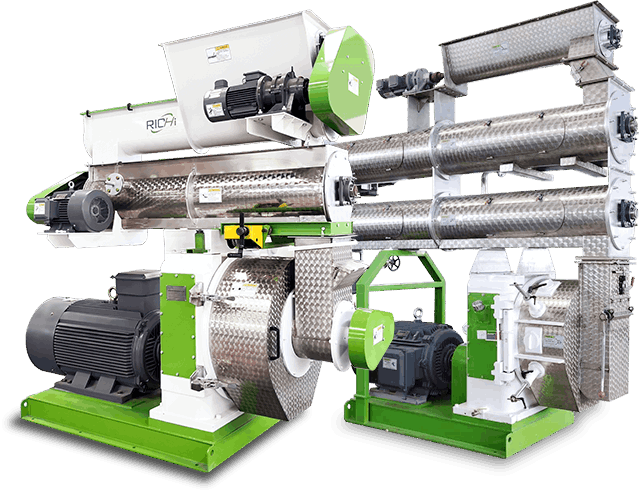

Option 2: Granular Organic Fertilizer Line (Higher Market Value)

Process Flow: Composting → Crushing → Mixing → Granulation → Drying → Screening → Packing

Additional Equipment:

- Mixer:

- Blends compost with additives

- Granulator:

- Type: Pan granulator or new type organic fertilizer granulator

- Pellet size: 3–6 mm

- Dryer (optional):

- For longer shelf life and better packaging

Advantages:

- Higher selling price

- Easier application by end-users

- Enhanced appearance and storage stability

5. Suggested Equipment Models for Small Scale Production

| Equipment | Model | Capacity | Power (kW) |

|---|---|---|---|

| Crawler Compost Turner | M2000 | 500–700 m³/day | 30 |

| Semi-wet Crusher | SWC-600 | 1–2 T/h | 22 |

| Horizontal Mixer | HM-600 | 0.5–1 T/batch | 7.5 |

| Pan Granulator | PG-800 | 1–2 T/h | 7.5 |

| Rotary Dryer (optional) | RD-0806 | 1–2 T/h | 5.5–7.5 |

| Rotary Screener | RS-800 | 1–2 T/h | 3 |

| Packing Machine | PM-50 | 20–50 kg/bag | 1.5 |

6. Plant Layout Design

Land Area Requirement: 300–800 square meters

Suggested Layout:

| Area | Function |

|---|---|

| Composting Yard | Windrow or groove fermentation |

| Processing Area | Crushing, mixing, pelletizing |

| Drying Area (if needed) | Space for rotary dryer/sun-drying |

| Finished Product Storage | Bagged fertilizer for sale |

| Office/Admin | Operation and quality control space |

Material Flow:

Raw manure → Compost → Crush → Mix → (Granulate) → (Dry) → Screen → Pack → Store

7. Investment and Cost Estimation

Initial Cost Breakdown:

| Item | Estimated Cost (USD) |

|---|---|

| Basic Equipment (Powder Line) | $10,000–$20,000 |

| Granulation Equipment (optional) | +$10,000–$15,000 |

| Compost Yard Construction | $2,000–$5,000 |

| Packing Machine | $2,000–$3,000 |

| Installation & Training | $1,000–$2,000 |

| Working Capital | $3,000–$6,000 |

| Total Estimate: | $18,000–$40,000 |

Operating Costs:

- Raw material (manure is usually free)

- Labor: 2–5 workers

- Electricity and fuel

- Maintenance and spare parts

8. Profitability Analysis

| Description | Powder Line | Pellet Line |

|---|---|---|

| Selling Price ($/ton) | $80–120 | $120–200 |

| Production (tons/month) | 100 | 80–100 |

| Monthly Revenue | $8,000–$12,000 | $9,600–$20,000 |

| Net Profit Margin | 30–50% | 35–60% |

| ROI Period | 6–12 months | 9–15 months |

9. Environmental Compliance

Local Certification:

- Register with local agriculture bureau or environment agency

- Ensure composting process eliminates pathogens (55°C for 3+ days) (Related post: 2T/H Compound Fertilizer Production Line in Austria)

Odor and Leachate Management:

- Use compost covers or biofilters

- Compost yard must be paved to prevent runoff

Dust Control:

- Equip crusher and screener with dust collection systems

10. Tips for Local Farmers and Cooperatives

- Start with powdered fertilizer if budget is tight.

- Form a cooperative to share investment and operation costs.

- Promote products through local markets and agricultural fairs.

- Train local youth in composting and processing techniques.

- Explore government subsidies or grants for waste treatment or organic agriculture.

Conclusion

A small-scale organic fertilizer production line offers a powerful way for local farms to transform waste into wealth. Whether producing powder or pellet organic fertilizers, the key lies in efficient composting, right-sized equipment, and good market positioning. With a well-designed production flow and proper management, even a modest plant can bring significant environmental and economic benefits.