Twin screw pet food extruder machines are known for their versatility in processing various types of pet food. A common question that arises is whether these machines can also be used to produce fish feed.

The answer is yes, twin screw pet food extruder machines can indeed process fish feed effectively, offering several advantages in aquaculture feed production. This article explores the capabilities of twin screw extruders in fish feed processing, their benefits, and considerations for manufacturers.

Adaptability of Twin Screw Extruders for Fish Feed

Twin screw extruders designed for pet food production are highly adaptable and can be effectively used for fish feed processing:

- Versatile Processing: These machines can handle a wide range of ingredients commonly used in fish feed, including fish meal, soybean meal, wheat flour, and various additives.

- Adjustable Parameters: Twin screw extruders allow for precise control over temperature, pressure, and shear, which is crucial for producing different types of fish feed.

- Floating and Sinking Feed: With proper adjustments, these extruders can produce both floating and sinking fish feed pellets, catering to different fish species and feeding habits.

Types of Fish Feed ProducibleTwin screw pet food extruders can process various types of fish feed:

- Floating Pellets: Ideal for surface-feeding fish species

- Slow-Sinking Pellets: Suitable for mid-water feeding fish

- Fast-Sinking Pellets: Designed for bottom-feeding fish species

- Micro-Pellets: For small fish or fry

- High-Protein Formulations: Suitable for carnivorous fish species

Advantages of Using Twin Screw Extruders for Fish FeedSeveral features make twin screw extruders particularly advantageous for fish feed production:

- High Protein Handling: These extruders can process formulations with high protein content, which is essential for many fish species.

- Improved Digestibility: The extrusion process can enhance the digestibility of ingredients, leading to better feed conversion ratios.

- Flexibility in Ingredients: Twin screw extruders can handle a diverse range of ingredients, allowing for the formulation of nutritionally balanced fish feeds.

- Consistent Quality: The precise control offered by twin screw extruders ensures uniform product quality, which is crucial for fish growth and health.

- Water Stability: Extruded fish feed typically has better water stability, reducing nutrient loss and water pollution in aquaculture systems.

- Scalability: These machines are available in various sizes, suitable for small-scale to large commercial fish feed production.

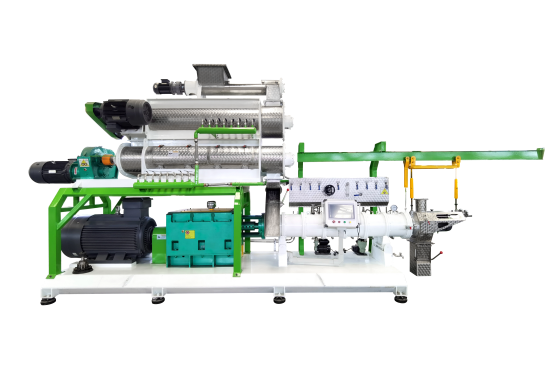

Twin Screw Extruder model demonstrates the adaptability of twin screw extruders for fish feed:

- Suitable for both freshwater and saltwater fish feed

- Capable of incorporating higher protein content in formulations

- Patented counter-rotating twin screw system for efficient processing

- Multiple injection ports for water and steam to control extrusion temperatures

- Capacity ranging from 0.5 to 12 tons per hour, depending on the model

Considerations for Fish Feed Production

While twin screw pet food extruders can be used for fish feed, some considerations are necessary:

- Formulation Adjustments: Fish feed often requires different nutrient profiles compared to pet food, necessitating formulation adjustments.

- Moisture Content: Fish feed typically requires higher moisture content than most pet foods, which may need adjustments in the extrusion process.

- Die Selection: Different die configurations may be needed to produce the specific sizes and shapes required for various fish species.

- Post-Extrusion Processing: Additional equipment like dryers and coolers may be necessary to achieve the desired final product characteristics.

- Regulatory Compliance: Ensure that the extruder and production process meet the specific regulations for fish feed production in your region.

Technological Advancements

Recent advancements in twin screw extrusion technology have further enhanced their suitability for fish feed production:

- Improved Screw Designs: Specialized screw configurations for better mixing and cooking of fish feed ingredients.

- Enhanced Control Systems: Advanced PLC systems for precise control over the extrusion process, ensuring consistent quality.

- Energy Efficiency: Modern twin screw extruders offer improved energy efficiency, reducing production costs.

- Integrated Systems: Some manufacturers offer complete extrusion lines specifically designed for fish feed, integrating pre-conditioning, extrusion, and post-extrusion processing.

Market Trends and Future Prospects

The ability of twin screw pet food extruders to process fish feed aligns well with current market trends:

- Growing Aquaculture Industry: The expanding aquaculture sector is driving demand for high-quality fish feed.

- Sustainable Formulations: Twin screw extruders can process alternative protein sources, supporting the trend towards more sustainable fish feed formulations.

- Functional Feeds: These extruders can incorporate functional ingredients like probiotics and immunostimulants, meeting the demand for value-added fish feeds.

- Customization: The flexibility of twin screw extruders allows for the production of species-specific and life-stage-specific fish feeds.

Conclusion

Twin screw pet food extruder machines demonstrate remarkable versatility in their ability to process fish feed effectively. Their adaptability to handle various ingredients, produce different types of pellets, and maintain consistent quality makes them valuable assets in aquaculture feed production.

The advantages of using twin screw extruders for fish feed, such as improved digestibility, water stability, and the ability to handle high-protein formulations, align well with the requirements of modern aquaculture. Manufacturers have developed specialized twin screw extruders that cater to both pet food and aqua feed production, highlighting the crossover potential of this technology.

However, it’s important for manufacturers considering the use of pet food extruders for fish feed to be aware of the specific requirements and potential adjustments needed. Factors such as formulation differences, moisture content, and regulatory compliance must be carefully considered.

As the aquaculture industry continues to grow and evolve, the demand for efficient and versatile feed production equipment is likely to increase. Twin screw extruders, with their proven track record in pet food production and adaptability to fish feed processing, are well-positioned to meet this demand.

Their ability to produce high-quality, nutritionally balanced fish feed can contribute significantly to the sustainability and productivity of aquaculture operations worldwide.

For manufacturers looking to diversify their product offerings or enter the fish feed market, investing in a twin screw extruder designed for both pet food and fish feed production can offer a strategic advantage. It provides the flexibility to meet diverse market demands and adapt to changing trends in both the pet food and aquaculture industries. (Related post: pet food production line price)